“CREATED AND DISTRIBUTED ECONOMIC VALUE” ASPECT

Economic performance of the Company is shown in created and distributed economic value table.

The created economic value present the main sources of the Company’s income, namely, income from electricity production, transmission and sale, as well as from the sale of coal and obtained remuneration.

The created value is distributed between suppliers and contractors, employees of the Company, shareholders and lenders, the state, as well as local communities.

|

Distributed economic value |

|

|---|---|

|

Payments to suppliers and contractors |

Operating expenses – payments to counterparties for materials, product components, equipment and services, rental payments etc. |

|

Payments to employees |

Payroll, social taxes and contributions, pension and insurance payments, expenses for medical services for employees and other forms of employee support |

|

Payments to capital suppliers |

Dividends to all categories shareholders and interest paid to lenders |

|

Payments to the Government |

Tax payments |

|

Investments to local communities |

Donations to charitable and non-governmental organizations and research institutions, expenses for supporting public infrastructure, as well as direct funding for social programs, cultural and educational activities |

According to results of 2020, the created economic value amounted to 382 bln tenge and the distributed economic value amounted to 313 bln tenge, as a result, the undistributed economic value amounted to 69 bln tenge. According to the approved Development Plan for 2021–2025, the created and distributed economic value is planned to be increased in 2021 and 2022.

Economic value, mln tenge

|

Indicator* |

2018 г. |

2019 г. |

2020 г. |

2021 г. |

2022 г. |

|---|---|---|---|---|---|

|

Actual |

Actual |

Actual |

Forecast |

Forecast |

|

|

Created economic value |

352 681 |

337 794 |

382 199 |

447 167 |

523 658 |

|

Sales proceeds |

351 100 |

336 233 |

380 990 |

446 568 |

523 369 |

|

Interest received (percent) |

1 581 |

1 561 |

1 209 |

599 |

289 |

|

Distributed economic value |

272 860 |

275 649 |

312 894 |

361 369 |

374 656 |

|

Payments to suppliers and contractors |

161 571 |

161 556 |

194 357 |

239 696 |

252 203 |

|

Payments to employees |

37 210 |

39 589 |

43 700 |

44 554 |

46 452 |

|

Payments to capital suppliers |

34 047 |

32 369 |

32 571 |

33 984 |

30 645 |

|

Payments to the government |

39 617 |

41 882 |

42 152 |

42 994 |

45 221 |

|

Undistributed economic value |

79 822 |

62 145 |

69 305 |

85 798 |

149 002 |

FINANCIAL ASPECTS AND OTHER RISKS AND OPPORTUNITIES FOR THE ORGANIZATION’S OPERATIONS RELATED TO CLIMATE CHANGE

Discussions over climate change issue continue across the globe for more than several decades. The United Nations Framework Convention on Climate Change (UNFCCC) signed in 1992 by more than 180 countries, confirms the international community’s concern about this issue.

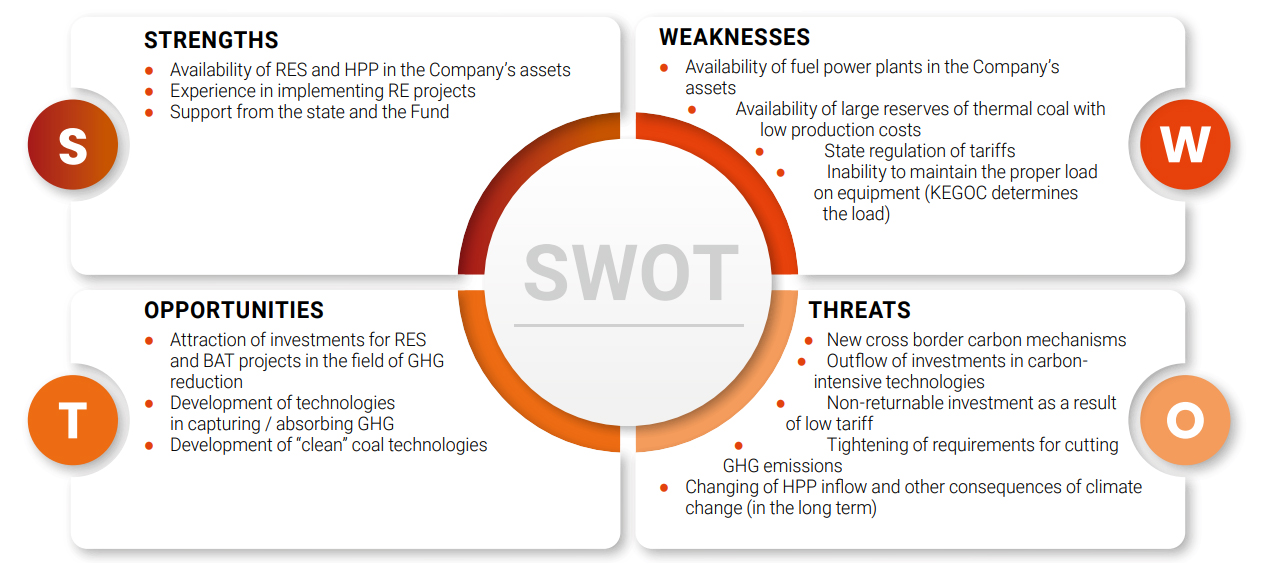

Relying on experts’ opinion, Samruk-Energy takes climate risk into account in defining the context of the organization and SWOT analysis when developing an energy transition strategy. To be fair one must mention that global decarbonization trends largely shaped by developed countries as opportunities, are more risks and challenges for emerging markets.

On the one hand, protraction in following global development trends results in social costs associated with man-made impact on the environment and restricting access to state-ofthe-art technologies and financial resources, but on the other hand, forcing the transition can lead to a loss of economic competitiveness, de-industrialization, and rise of electricity prices, job сuts in traditional industries, not to mention the problems associated with the need to ensure the reliability of energy supply.

Guided by principles of sustainable development, to maintain an optimal balance between the economic accessibility of electricity, security of supply and environmental and social sustainability, Samruk-Energy prefers a well-considered and gradual energy transition, whereby renewable energy sources will be used along with conventional ones, considering that this direction is well-targeted path for development of fuel and energy sector of Kazakhstan.

At the same time, the existing experience in the implementation of projects in the field of alternative energy sources indicates the presence of several issues that need to be addressed at the state level.

The main directions and goals for reducing the carbon intensity of the Company’s processes and products are described in the long-term Development Strategy and Environmental Policy of the Company. Thus, considerable attention at the Company is paid to the development of RES and HPP, energy management systems were introduced everywhere, comprehensive programs were developed to improve energy efficiency and energy conservation, and a serious project on gasification of Almaty power plants is planned to be implemented. EPA regulate the Сompany’s highest emitting subsidiaries through the national greenhouse gas emissions trading system, which was created to achieve the national contribution declared in the Paris Agreement of –15 % by 2030 from the 1990 level.

SWOT ANALYSIS OF SAMRUK-ENERGY STANDING WITH REGARD TO CLIMATE CHANGE ISSUE

“INNOVATIVE DEVELOPMENT AND DIGITIZATION” ASPECT

Innovative development

The Company’s development strategy provides for the provision of reliable competitive supplies of energy resources in the markets where it operates through the deployment of innovative technologies that increase the efficiency and environmental friendliness of coal generation sources.

The research “Development of the technology of furnace devices for boiler units for firing high-ash coal from Ekibastuz deposit’s layer No.3 and depleted coal/coal by-products” was conducted in collaboration with Nazarbayev University. The research execution period is 2018–2020.

In order to conduct research work, a joint research laboratory “Clean Coal Technologies” was established at the premises of the “Nazarbayev University Research and Innovation System” PI.

The following works were performed in 2020:

- Pre-commissioning activities and experimental studies on combustion, air and steam-air gasification of high-ash Ekibastuz coal, carbonaceous rocks and coal by-products was conducted in superadiabatic combustion mode (AGSS). ●

- Continuation of experimental studies on firing of high-ash Ekibastuz coal by-products on сombined unit of fluidized bed and circulating fluidized bed (CU FB CFB). ●

- Experimental research on air, steam-air and steam-oxygen gasification of high-ash Ekibastuz coal and its by-products at atmospheric pressure in CB and CFB was conducted. ●

- Mathematical model was developed and calculations for steam-oxygen gasification of high-ash Ekibastuz coal were made. ●

- Development of technical proposals for the concept of industrial and power boilers with FB and CFB for firing high-ash Ekibastuz coals and its by-products.

The outcome: ●

- The data confirming the possibility of efficient combustion of high-ash coal by-products in the FB and CFB were obtained;

- The data on the influence and improvement of operating conditions of the boiler were obtained; such conditions ensure the best environmental performance (minimization of sulfur and nitrogen oxides emissions) when firing highash coal by-products in FB and CFB;

- Data regarding the influence of Ekibastuz coal ash content on the gasification process were obtained;

- Data on the influence of operating factors on the process of air, steam-air and steam-oxygen gasification were obtained;

- A comparative analysis of FB and CFB furnaces was conducted in order to select the most preferable technology for firing high-ash Ekibastuz coal and its by-products depending on the ash content of coal waste;

- Final report with proposals on using high-ash Ekibastuz coal and its by-products for power production was released.

To improve technical and economic indicators when firing high-ash coals at thermal power plants of the Company, the possibility of introducing the technology fuel oil free startup of boiler system (plasma-fuel system) was explored.

The project implementation will allow solving the following tasks:

- stabilization of the combustion of a pulverized coal torch at reduced loads of boiler units;

- elimination of fuel oil consumption in the flame combustion of low-grade coals;

- elimination of the negative effects of co-firing of coal and fuel oil in one furnace volume, which lead to a decrease in the efficiency and reliability of the boiler.

This technology has been successfully applied in the People’s Republic of China, the Russian Federation, Indonesia, etc. at power units from 200 to 1,000 MW. The project implementation was approved by the resolution of “Samruk-Energy” JSC Board of Directors at the meeting on December 14, 2020.

Digitization

Using the potential of digital technologies will allow the Company to boost productivity, safety at work and reduce the cost of production of goods and the delivery of services, which in turn will contribute to the implementation of the strategic initiative “Improving the efficiency of operations”.

The Сompany aims to ensure digitization by incorporating digital principles into corporate strategy, business model, activities and culture:

- 1. Business orientation

- 2. Partnerships with business

- 3. Search for best practices

- 4. Timely implementation of projects with agreed budget

- 5. Automation of processes

- 6. Transition to digital format

Project SKE.03.01P “Implementation of automatic frequency and power control”

The project is being implemented for the first time in the EEC and is a joint project with “KEGOC” JSC, implemented under the Digital Kazakhstan state program.

Due to the ALFC, “KEGOC” JSC will regulate and control the power of the stations of the “Samruk-Energy” JSC group of companies within the specified limits, i.e influence directly on power units / hydraulic units (decrease or increase of power) in real time when the circuit-mode situation in the power system changes.

Phase 1 – “Conceptual Design” was completed in 2020. At the moment, the implementation of phase 2 – “Implementation” has begun. Within the framework of Phase 2 – “Implementation”, the development of design and estimate documentation has been completed and construction and installation work is underway.

“Business Loss Analysis Using Data Analytics”

Project It is implemented in “AZhC” JSC and allows to store and manage large amounts of data on electricity consumers, as well as search for anomalies in order to identify possible commercial losses. In 2020, as part of the initiation of the project, a technical specification was developed, as well as marketing of prices.

An on-site examination was carried out, as well as analysis of more than 28 thous. electricity consumers of “AZhC” JSC using a data analytics system.

Project “Implementation of a pilot automated medical examination system”

In order to increase the level of safety of working personnel and the entire enterprise as a whole, and also to increase the efficiency of the medical examination procedure, the event “Implementation of the pilot of an automated medical examination system” was initiated at “Ekibastuz GRES-1” LLP and at TPP-3 of “APP” JSC. Two complexes of hardware and software were installed, tests were carried out.

“ENERGY EFFICIENCY” ASPECT

Energy

The Company’s energy policy places a priority on energy conservation and improvement of energy efficiency, which contributes to reduction of energy consumption and minimization of the environmental impact.

The Head office of the Company consolidates and analyzes data on energy consumption and key energy efficiency indicators across “Samruk-Energy” JSC group of companies, compares it with past periods and identifies opportunities for improvement.

The Company’s activities in the field of energy conservation and energy efficiency are based on the methodology of international standard ISO 50001 “Energy management systems”.

The Company has the program for energy conservation and improvement of energy efficiency for 2015–2025. This program is a key instrument for planning and implementing activities in the field of energy conservation and energy efficiency.

The Program aims to develop measures for wise and economically feasible use of fuel and energy resources.

A 10.5 % decrease in power consumption of the gross marketable product of SA in 2025 compared to the base 2014 is the expected effect from the program implementation.

Target-oriented tools of the Program:

- setting targets for energy conservation and energy efficiency for SA;

- continuous monitoring of the achievement of specified targets through energy-economic analysis in line with the developed methodology for calculating key energy efficiency indicators;

- development, implementation and improvement of the energy management system at SA;

- implementation of organizational and technical activities on energy conservation and energy efficiency in compliance with the approved action plans for energy conservation and energy efficiency across SA;

- carrying out standard activities aimed at energy conservation and energy efficiency at SA;

- creation of an integrated system for automated metering of energy resources consumption.

As part of the ongoing work on energy conservation and improvement of energy efficiency, 62 measures aimed at reduction of fuel and energy resources consumption were implemented during the last year, which allowed saving 406 thous. tons of standard fuel across “Samruk-Energy” JSC group of companies.

Energy consumption within the organization

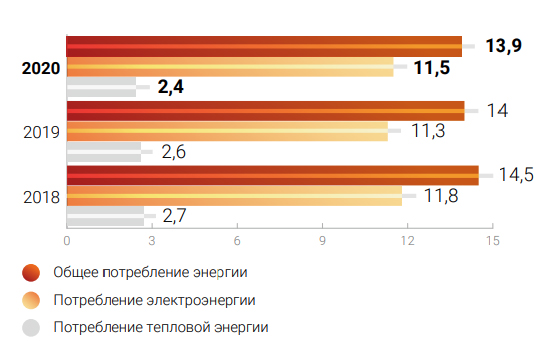

The total energy consumption has a steady decline during the period under review 2018–2020 in relation to the base 2014 (17.7 mln GJ).

In the reporting year, 13.9 mln. GJ of energy was consumed, including 2.6 mln GJ from renewable energy sources. In general, over the years, there is a positive trend towards an increase in energy consumption from RES, which is driven by the growth of RES share in the country’s electricity production.

At year-end 2020, the growth of fuel consumption (coal and gas) was resulted in an increase in electricity production at ESDPP-1 and the growth of heat output at Almaty Power Plants.

The growth of fuel consumption the organization (coal and gas)

|

Consumption within the organization |

2018 г. |

2019 г. |

2020 г. |

|---|---|---|---|

|

Total fuel consumption, mln GJ, incl: |

310.5 |

291.2 |

306.3 |

|

Coal |

298.1 |

279.9 |

291.8 |

|

Gas |

10.0 |

9.2 |

12.0 |

|

Fuel oil |

1.2 |

0.8 |

0.9 |

|

Petroleum |

0.2 |

0.2 |

0.2 |

|

Diesel |

1.2 |

1.2 |

1.2 |

|

Electricity consumption, mln GJ |

11.8 |

11.3 |

11.5 |

|

incl. from RES |

1.0 |

1.3 |

2.6 |

|

Heat consumption, mln GJ |

2.7 |

2.6 |

2.4 |

|

incl. from RES |

– |

– |

– |

|

Total energy consumption, mln GJ |

14.5 |

14.0 |

13.9 |

|

incl from RES |

1.0 |

1.3 |

2.6 |

Energy intensity

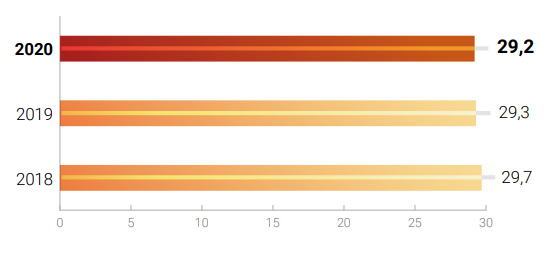

The volumes of consumption of fuel and energy resources within the organization, as well as volumes of electricity and heat produced, electricity transmitted and coal mined were used in this indicator. According to the 2020 results, the energy intensity of the gross commodity product across “Samruk-Energy” JSC group of companies amounted to 29.2 t.s.f / mln tenge and decreased compared to the previous year figure.

Heat consumption also decreased in relation to the base year (3.7 mln GJ), and so in relation to the last year and amounted to 2.4 mln GJ. In general, there is a trend towards reduction in total energy consumption over the years in relation to the base year 2014 (17.7 mln GJ). The reduction in total energy consumption was driven by reduction of energy use for power plant needs.

Energy intensity, mln tenge

*Ton of conventional fuel

*Ton of conventional fuel

Total energy consumption, mln GJ

The reduction of energy consumption

Electricity consumption has decreased in relation to base year (14.0 mln GJ), it slightly increased in comparison with the last year and was 11.5 mln GJ

ASPECT “MATERIALS USED”

The products of “Samruk-Energy” JSC are thermal and electric energy, as well as thermal coal.

The regulation of this industry is carried out by state bodies represented by the Ministry of Energy of the Republic of Kazakhstan and the Committee for the Regulation of Natural Monopolies of the Ministry of National Economy of the Republic of Kazakhstan.

Electricity and heat were produced using fossil fuels. Chemical reactions occurring during the combustion of coal, gas and fuel oil lead to the natural formation of a number of substances, which, in the absence of appropriate control, can lead to a loss of the required quality of the environment. For such control, Kazakhstan has a system of state regulation in the form of environmental and natural resource law (for more details, see the section “Environmental Category”). The company does not carry out any marketing communications regarding the manufactured product, including advertising and promotion.

List of materials used in our facilities in the manufacture of products

|

In the production of electricity: |

Measurement unit |

Materials used |

||

|---|---|---|---|---|

|

Volume |

||||

|

2018 г, |

2019 г. |

2020 г. |

||

|

Coal |

tons |

17 619 007 |

16 565 570 |

16 652 949 |

|

Fuel oil |

tons |

15 010 |

15 746 |

19 925 |

|

Gas |

thous. m3 |

35 928 |

38 472 |

46 370 |

|

In the production of heat: |

Measurement unit |

Materials used |

||

|---|---|---|---|---|

|

Volume |

||||

|

2018 г. |

2019 г. |

2020 г. |

||

|

Coal |

tons |

839 883 |

764 291 |

1 446 269 |

|

Fuel oil |

tons |

14 031 |

2 358 |

1 740 |

|

Gas |

thous. m3 |

251 620 |

226 580 |

284 914 |

|

For auxiliary needs in the production of both types of products: |

Measurement unit |

Materials used |

||

|---|---|---|---|---|

|

Volume |

||||

|

2018 г. |

2019 г. |

2020 г. |

||

|

Petroleum |

t.n.f |

3 588 |

3 570 |

3 656 |

|

Diesel fuel |

t.n.f |

25 210 |

28 586 |

34 662 |

ASPECT “INFORMATION POLICY AND SECURITY”

As part of improving stakeholder engagement, there is a Communication Strategy at “Samruk-Energy” JSC, which involves a single approach to corporate communications, determines the target audience, communication principles, media planning, anti-crisis response, internal and external PR tools and external positioning of the Company.

The mission of the Communication Strategy:

To ensure a positive image of the Company by offering target audiences complete, most transparent and relevant information about operating results.

Vision of the Communication Strategy:

A well-established communication channels, which enable to raise the Company to the level of a leader of public opinion and influence regarding the development of Kazakhstan’s power sector.

Moreover, there is an Information Policy at the Company that determines the principles, procedure, timeframe, list and methods of disclosing information, types of information, stakeholder engagement, including cooperation with shareholders and investors, measures for protection of information, monitoring and quality control of disclosed information.

The primary aim of information security is “SamrukEnergy” JSC information and data protection, as well as its supporting infrastructure from any accidental or malicious actions. Any hacker attack threatens to damage data and information, as well as its owners or supporting infrastructure. The tasks of ensuring information security are set out in the Company’s Information Security Policy, monitoring and control, forecasting and preventing such incidences, as well as minimizing damage from their implementation.

No confidential information leakage was admitted in 2020. Monitoring of user actions made when using personal computers showed a significant decrease in violations of “Samruk-Energy” JSC internal regulatory documents on information security in comparison with previous years. In 2017, the project “Introduction of the system for management and ensuring information security” was launched as part of Transformation Program.