ASPECT “COMPLIANCE WITH REQUIREMENTS”

Explanation of the essential topic and its boundaries

Being the largest electricity holding company in Kazakhstan, “Samruk-Energy” JSC is aware of the importance of the environmental aspect in a sustainable development of the company. Environmental protection and efficient use of resources play an important role in operations of the Company and its subsidiaries and affiliates.

The RK Environmental Code classifies primary production activities of “Samruk-Energy” JSC subsidiaries as special nature management, and these activities are regulated by the relevant requirements and standards. Thus, each subsidiary and affiliate of “Samruk-Energy” JSC is responsible for its environmental footprint within the obtained environmental permit and other conditions of special nature management.

The RK environmental legislation encourages nature users to reduce their impact on the environment using economic incentive mechanisms. So, the new Environmental Code of the Republic of Kazakhstan was approved on 02.01.2021, whereby the “polluter pays” principle was revised and significantly strengthened.

Of course, in environmental protection, we, first off, adhere to existing legislative requirements and norms in Kazakhstan, but at the same time we strive to comply with more stringent standards of developed countries, consistently implementing a number of energy-saving, material-saving and environmental protection measures.

Management approach

Taking into account the existing experience and specific features of technologies used, the available types of fuel, peculiarities of our climate, as well as a number of other motivating and sometimes constraining factors сommon to sustainable development concept, we have developed an environmental policy as a comprehensive long-term program, which is part of the Company’s Development Strategy.

To manage environmental safety – as part of comprehensive occupational safety – an environmental management system (EMS) has been established at “Samruk-Energy” JSC group of companies, which is a component of corporate governance system and an essential part of non-financial risk management system. EMS at “Samruk-Energy” JSC is constantly assessed for compliance with the best world practices with the involvement of independent international consultants and is improved step by step. All subsidiaries and affiliates of the Company engaged in production activities have implemented the ISO 14001 “Environmental Management” standard.

In accordance with the approved Long-Term Strategy, the Company plans to seek to reduce the impact of production activities on the environment by modernizing existing technologies and using renewable energy sources.

As preventive measures, a continuous environmental assessment of the effectiveness of production processes is conducted through industrial environmental monitoring. The monitoring is based on measuring and calculating the rate of emissions into the environment, harmful production factors. Industrial environmental monitoring is carried out with the involvement of independent laboratories accredited in the manner established by the RK legislation in the field of technical regulation. Atmospheric air, surface and underground waters, soils are the objects of industrial monitoring.

In addition, in case of emergencies, compulsory environmental insurance and liquidation funds are provided in accordance with the requirements of the Republic of Kazakhstan legislation.

Assessment of management approach

Particular attention is paid to the new technologies: RES development, oil fuel-free start-up and other energy-efficient technologies.

The Company has successfully implemented several investment projects in RES and HPP sector since 2013: 300 MW “Moynak HPP” JSC, 45 MW First wind power plant, 2 MW solar power plant, retrofit of “Shardarinsk HPP” JSC with an increase in capacity to 126 MW.

Given the large reserves of coal in Kazakhstan and its attractiveness in terms of price, it is feasible to support the development of innovative technologies to improve its environmental characteristics. To this end, the Company established the Clean Coal Technologies research laboratory together with “Nazarbayev University AEO”.

Moreover, the Company implements a comprehensive environmental protection activities program, which provided the following results at the end of 2020:

- lack of emergency spills and other types of emissions;

- the share of “clean” energy production – RES and HPP – 8.7 % of the total output of the company’s group;

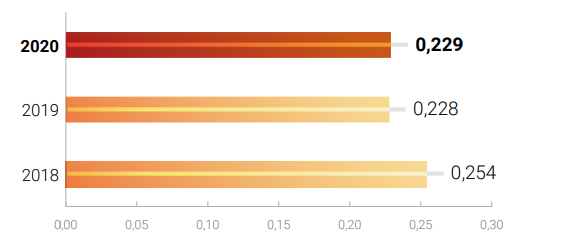

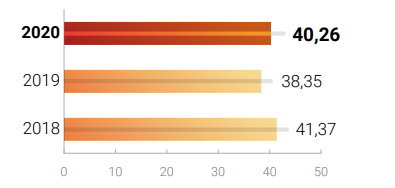

- among the group of companies, the specific emission of pollutants per 1 kWh of production decreased by 3.8 % compared to 2019. For 3 years (2018–2020), there has been a positive trend in reducing the specific emissions of nitrogen oxides by 4 % and dust by 1.5 %;

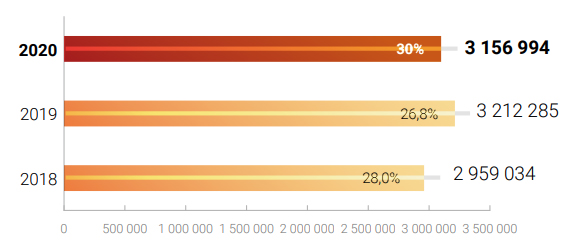

- the specific indicator of ash and slag waste formation decreased by almost 10 % over 3 years (2018–2020) in the fuel generation sector.

At the end of 2020, a mandatory environmental audit at the enterprises of the “Samruk-Energy” JSC group was not carried out due to the lack of grounds established by law, which include significant damage to the environment, reorganization or bankruptcy of legal entities-users of natural resources engaged in environmentally hazardous economic and other activities.

To prevent damage to the environment, the legislation involves environmental inspections, which may result in imposing fines for violating legislation requirements. 5 inspections were carried out in 2020 – 2 times at “SDPP-1” LLP, “SDPP-2” JSC – 2 times, “APP” JSC and “Bogatyr Komir” LLP. Some violations of requirements of legislative acts were revealed, the amount of fines amounted to 14.45 mln tenge. All fines were paid in full. Corrective activities were carried out.

The monetary value of significant fines and the total number of non-financial sanctions for non-compliance with environmental laws and regulations

|

|

Measurement unit |

Amount |

||

|---|---|---|---|---|

|

2018 г. |

2019 г. |

2020 г. |

||

|

The sum of money of significant fines |

thous. tenge |

721,5 |

4 751 |

14 448 |

|

number of cases when non-financial sanctions were applied |

– |

0 |

0 |

20 |

|

Cases filed through dispute resolution mechanisms |

– |

– |

– |

3 |

The analysis of the audit materials showed that violations of the law are allowed mainly not at the examination, but at auxiliary processes. For example, for the processes in coal warehouses, for industrial sites, and for earthworks during small construction operations and for the low culture of line personnel when dealing with consumer waste.

In 2020, 3 applications of individuals and legal entities with complaints on the topic of environmental protection were recorded. All cases were reviewed and processed in accordance with the internal complaints mechanism.

Total expenditures and investments in environmental protection broken down by types

The Company implements a comprehensive environmental protection activities program covering such aspects as:

- protection of atmospheric air;

- reduction of greenhouse gases;

- reclamation of ash dumps;

- waste management;

- protection and efficient use of water resources;

- implementation of management systems and the best safe technologies;

- R&D and other works;

- environmental training and advocacy.

In line with existing law of the RK, “Samruk-Energy” JSC group of companies have an environmental protection action plan agreed with the authorized body, the implementation of which is mandatory requirement for special environmental management

|

|

Measurement unit |

Amount |

||

|---|---|---|---|---|

|

2018 г. |

2019 г. |

2020 г. |

||

|

* costs associated with waste management and cleaning of emissions, discharges, as well as the elimination of environmental damage |

thous. tenge |

6 556 645 |

4 242 256 |

5 604 706 |

|

** expenses for the prevention of environmental impact and environmental management system |

|

72 616 |

373 908 |

286 567 |

ASPECT “WATER AND WASTE WATER”

Explanation of the essential topic and its boundaries

Water is a unique substance and an essential component of all living creatures on Earth. Along with that, water is used in many processes in production of goods necessary for human life.

Historically the water has played a great role in power industry: at “Samruk-Energy” JSC group of companies, water is used not only as a driving force for hydro and steam turbines, but also for feeding reservoirs and compensating for losses in other processes, to irrigate ash beaches, to maintain the water level in ash dumps, and for public living needs of employees.

“Samruk-Energy” JSC objectives regarding water resources protection is to minimize the impact, including:

- decrease in the volume of fresh water consumption;

- increase in the share of reused water;

- reduction of wastewater discharges and concentrations of harmful substances in wastewater

Water intake

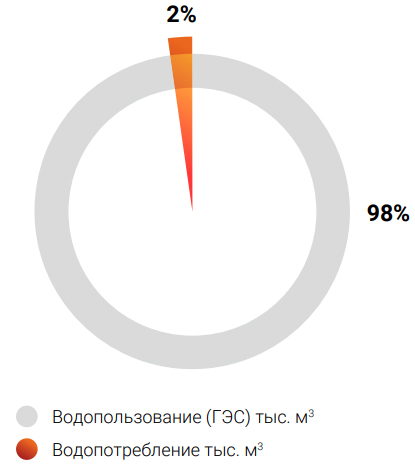

Considering that “Samruk-Energy” JSC’s portfolio includes hydropower and thermal power plants, we classify interaction with water into water use and water consumption, respectively. At the same time, 98 % of the volume of water withdrawn is classified as water use at HPPs, and 2 % – as water consumption. “Samruk-Energy” JSC group of companies does not consume water in regions that experience water shortage.

Management approach Interaction with water as natural resource

Interaction with water resources at “Samruk-Energy” JSC SA is regulated and managed in accordance with the current legislation of the RK. Subsidiaries of “Samruk-Energy” JSC withdraw water in volumes determined by production needs in accordance with the developed projects and regulations that are agreed with authorized state agencies.

Thus, the main sources of water for technological needs are: Sharyn River and Bestyubinsk Reservoir (Moinak Hydropower Plant), the Syrdarya river and Shardara reservoir (Shardarinsk Hydropower plant), channel named after K. Satpayev (“Ekibastuz SDPP named after Bulat Nurzhanov” LLP, “Ekibastuz SDPP-2 Plant” JSC), Shidertinsky channel (“Ekibastuz SDPP-2 Plant” JSC), Big Almaty Lake and the basin of Big Almaty Lake (Cascade of HPP), Kapshagay Reservoir (Kapshagay HPP).

To save water, reverse water supply systems with a bulk reservoir-cooler and once-through hydraulic ash removal systems are used at Ekibastuz stations and Almaty power plants use recirculating water supply systems with cooling towers as well as reuse wastewater from ash dumps.

Water discharge related impact management

Wastewater of production enterprises of “Samruk-Energy” JSC group of companies consists of industrial and domestic wastewater. The main volume of wastewater is industrial wastes; they are not discharged into natural sites. They are used as hydrotransport to remove ash and slag waste to ash dumps.

Permissible standards for content of pollutants in wastewater and their volume are established by law. Before being discharged, wastewater is properly treated to the approved sanitary and hygienic standards.

Moreover, to avoid environmental damage, analytical monitoring of processes of changing water and temperature regimes of groundwater through a network of observation wells, repair of equipment and pipelines of HAH system is carried out on a regular basis.

During the reporting period, there were no emergency discharges and spills of oils, fuel, waste, chemicals, and other substances that caused damage to the environment.

ASSESSMENT OF THE MANAGEMENT APPROACH

Subject disclosure:

|

|

All areas Megaliters |

Areas experiencing water shortage |

|||

|---|---|---|---|---|---|

|

2018 |

2019 |

2020 |

|||

|

Water intake |

|||||

|

The volume of water taken by sources |

|||||

|

from surface water sources (total) |

10,498,150 |

11,924,598 |

10,473,288 |

no |

|

|

fresh water (≤1,000 mg /l of total dissolved solid) |

10,498,150 |

11,924,598 |

10,473,288 |

no |

|

|

other water (> 1,000 mg /l of total dissolved solid) |

0 |

0 |

0 |

no |

|

|

from underground sources (total) |

7,341 |

6,630 |

6,061 |

no |

|

|

fresh water (≤1,000 mg /l of total dissolved solid) |

0 |

0 |

0 |

no |

|

|

other water (> 1,000 mg /l of total dissolved solid) |

7,341 |

6,630 |

6,061 |

no |

|

|

sea water (total) |

0 |

0 |

0 |

no |

|

|

fresh water (≤1,000 mg /l of total dissolved solid) |

0 |

0 |

0 |

no |

|

|

other water (> 1,000 mg /l of total dissolved solid) |

0 |

0 |

0 |

no |

|

|

stratal water (total) |

0 |

0 |

0 |

no |

|

|

fresh water (≤1,000 mg /l of total dissolved solid) |

0 |

0 |

0 |

no |

|

|

other water (> 1,000 mg /l of total dissolved solid) |

0 |

0 |

0 |

no |

|

|

from public and other water supply systems |

40,577 |

44,917 |

36,227 |

no |

|

|

fresh water (≤1,000 mg /l of total dissolved solid) |

40,577 |

44,917 |

36,227 |

no |

|

|

other water (> 1,000 mg /l of total dissolved solid) |

0 |

0 |

0 |

no |

|

|

Total water volume from public and other water supply systems |

|

|

|||

|

surface |

40,577 |

44,917 |

36,227 |

no |

|

|

underground |

0 |

0 |

0 |

no |

|

|

sea |

0 |

0 |

0 |

no |

|

|

stratal |

0 |

0 |

0 |

no |

|

|

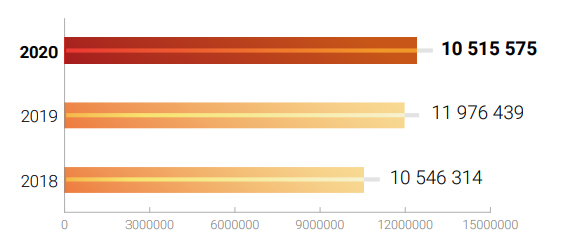

The total amount of water taken |

10,546,314 |

11,976,439 |

10,515,575 |

no |

|

|

Discharge |

|||||

|

Discharge by types |

|||||

|

Surface |

77,001.4 |

73,751.3 |

75,313 |

no |

|

|

Underground |

0 |

0 |

0 |

no |

|

|

Sea |

0 |

0 |

0 |

no |

|

|

Public and other water supply systems |

0 |

0 |

0 |

no |

|

|

Volume of wastewater given for use to other organizations |

0 |

0 |

0 |

no |

|

|

Total discharge |

77,001.4 |

73,751.3 |

75,313 |

no |

|

|

Wastewater according to treatment level |

|||||

|

Without purification |

|

|

|

|

no |

|

Before fishery requirements |

Required level of purification |

|

|

|

no |

|

Before cultural and household requirements |

Required level of purification |

|

|

|

no |

|

Other |

MPD norms |

77,001.4 |

73,751.3 |

75,313 |

no |

|

Water consumption |

|||||

|

Total water consumption |

201,229 |

198,438 |

197,838 |

no |

|

|

Water use |

|||||

|

Total water consumption |

10,345,085 |

11,778,000 |

10,317,737 |

no |

|

|

WATER EFFICIENCY OF PRODUCTION |

|||||

|

|

|

All areas m3/kWh |

|

||

|

The volume of water withdrawn per unit of output |

0.333 |

0.396 |

0.335 |

no |

|

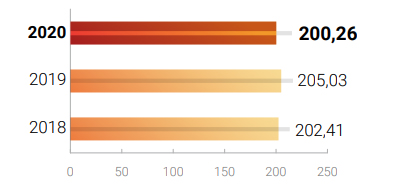

The share and total volume of recycled and reused water for the reporting period:

Total volume of water withdrawn, thous. m3

The volume of recycled and reused water, thous. m3

ASPECT “BIODIVERSITY”

Explanation of the essential topic and its boundaries

Given that the portfolio of “Samruk-Energy” JSC includes hydropower plants, renewable energy sources and RECs, the Company evaluates the “Biodiversity” aspect as significant in relation to these assets. However, we believe that fuel stations of “Samruk-Energy” JSC and coal mines of “Bogatyr Komir” LLP do not have a direct negative impact on wild vegetation and animals because they are located within settlements or in industrial areas, as well as taking into account that the scarcity of biodiversity of the construction site was considered as an environmental solution during the design of these production facilities.

Thus, “Samruk-Energy” JSC subsidiaries’ operations may have a negative impact on the ornithological fauna, fish fauna and other freshwater ecosystems, as well as on the flora and fauna of coastal zones within zones of impact of “Shardarinsk HPP” JSC, “Moynak HPP” JSC, Cascade of HPP, Kapshagay HPP, as well as “FWPP” LLP and “AZhC” JSC.

Management approach

At planning production activities, an environmental impact assessment including on the flora and fauna is performed at “Samruk-Energy” JSC group to minimize adverse effect on biodiversity. The EIA procedure is regulated by the legislation of the Republic of Kazakhstan. Monitoring of the impact on the flora and fauna during further operation of enterprises is also regulated.

Evaluation of management approach

At the stage of design, FWPP made provisions to reduce the environmental impact of wind power plants – given that light pollution leads to disruption of the biorhythms of living creatures, nighttime wind turbine lighting is minimized up to the use of only sidelights.

At “AZhC” JSC, to minimize the cases of death of birds on overhead lines from electric shock, lines are reconstructed by equipping with insulated wires.

In order to minimize the death of fish on water turbines, all hydropower plants are equipped with fish protection devices. In addition, based on the recommendation of Kazakh Research Institute of Fisheries, as a fish protection measure, the surface of the water at night is illuminated by spotlights near the water intake in front of the turbine water conduits, thus light spots scare the fish. The movement of fish occurs through bends for idle spillway (IS). To reduce the impact on water and terrestrial (coastal) ecosystems, the operating modes of hydropower plants are agreed with the Committee for Water Resources of the Ministry of Ecology, Geology and Natural Resources of the Republic of Kazakhstan, mayor administrations, as well as with the management of SPNR (for example, in the case of Moynak HPP). Visual field observations were introduced at HPP and WPP to monitor the impact on the plant and animal world.

Protected and rehabilitated habitats

In 2020, “Samruk-Energy” JSC did not operate in territories that have any special sanitary or environmental regime or the status of specially protected natural territories.

|

Location with respect to a protected area or area of high biodiversity value outside protected areas |

Type of operations |

The value of biodiversity, characterized by a feature of a protected area or area with high biodiversity value outside the protected area. |

Territory management status / class |

|---|---|---|---|

|

“FWPP” LLP (Ereymentau city, Akmolinsk region) |

|||

|

Buyratau State National Natural Park is 45 km away |

Electricity production |

There are 2 species of birds included in the Red Book of Kazakhstan in Ereymentau mountains (imperial eagle and steppe eagle). However, clusters of birds were found in lowlands and forest plantations along highways and railways, which in turn are located away from the wind turbines installed at the WPP. Cases of collision with the wind turbine blades since the facility was commissioned were not reported. |

Natural park |

|

Moynak HPP (Almaty region) |

|||

|

The Charyn National Park is located downstream of the Charyn River at about 55 km away from the Moynak Hydro power plant |

Electricity production |

“Moynak HPP” JSC cooperates with UNDP experts in Kazakhstan on the project for preservation of relic aspen grove, which is located downstream of the Charyn River. |

Natural park |

ASPECT “EMISSIONS”

Explanation of the essential topic and its boundaries

For “Samruk-Energy” JSC, the aspect of the impact on air from production activities of its TPPs is the most significant in comparison with other environmental aspects. This is logical, because the majority of electricity produced by the Company’s group (in 2020 – 91.3 %) is generated using fossil fuels, resulting in origination of flue gases that pollute the atmospheric air. At the same time, because of chemical reactions that occur during fuel combustion, greenhouse gases are released into the air, affecting climate change.

Management approach to reducing greenhouse gas emissions

Kazakhstan ratified the Paris Agreement in 2015, thus reaffirming its commitment to the global fight against climate change. “Samruk-Energy” JSC takes climate change seriously. The main directions and goals for reducing the carbon intensity of processes and products are described in the longterm Development Strategy and the Environmental Policy of the Company. Thus, the strategic goals of the Company include the development of renewable energy and hydropower plants, energy management systems have been introduced everywhere, comprehensive programs on increasing energy efficiency and energy conservation were developed.

As part of supporting RES, conditional consumers of “SamrukEnergy” JSC group purchased 765 mln kWh of “green” energy in 2020. Expenditures for purchase of electricity from RES across the group amounted to circa 28 bn tenge, which is twice the volume of 2019 (378 million kWh).

In addition, such subsidiaries of “Samruk-Energy” JSC as “Ekibastuz SDPP-1” LLP, “Ekibastuz SDPP-2 Plant” JSC, “APP” JSC and “Bogatyr Komir” LLP are facilities that were set quotas and have obligations to reduce GHG emissions as part of the national GHG emissions trading system.

Management Approach to emissions of significant pollutants

The main sources of pollutant emissions in the Company are 1st category fuel stations. Significant substances common to TPP are nitrogen oxides, sulfur oxides, carbon monoxide, dust (ash).

The efficiency and correctness of environmental decisions taken during the design of stations is confirmed by the years of their operation. The choice of construction site for Ekibastuz stations of national importance is not a coincidence – proximity to the fuel source has been provided, which minimizes the negative impact of coal transportation, and most preferable conditions for dispersion of pollutants such as the height of the chimneys, the location that considers the topography and wind pattern, remoteness from residential areas were ensured.

Taking into account the opinion of the public and authorized bodies, gasification of CHP-2, 3 is planned at Almaty stations located in urban agglomeration in addition to the CHP-1 and WHC already converted to gas.

Emissions into the air are strictly regulated by environmental legislation. Air pollutant emissions are produced in volumes determined by production processes in accordance with the developed projects and standards, which are agreed with authorized state agencies and specified in special permits.

To minimize ash emissions, ash collecting technologies are used – at Ekibastuz state district power plants these are electrostatic precipitators, and at Almaty TPPs – new generation emulsifiers. To suppress the production of other gases, low-emission burners are used, the modes are regulated thanks to the high pressure heaters and 4th steam extraction.

Permanent industrial environmental monitoring of compliance with the standards for maximum permissible emissions is carried out and reports are submitted to the regulatory body on a regular basis.

Evaluation of management approach

According to the 2020 results, the volume of electricity production by renewable energy sources (RES) of the group amounted to about 336 mln kWh, thus Samruk-Energy share in RES market was about 10 %.

Shardarinsk HPP complete retrofit program was finished in 2020 – the reconstruction increased the capacity of the HPP from 100 MW to 126 MW, which will provide an additional increase in the share of “clean” energy.

The decision on gasification of Almaty CHP-2 was taken in 2020, which will enable to improve the environmental situation in the southern metropolis. At the same time, it is planned to implement the project on reconstruction of Almaty CHP-3 with an increase in the installed capacity to 450 MW.

According to the 2020 results, the following was achieved across the group of companies:

- lack of emergency situations that resulted in environmental damage;

- the share of “clean” energy production – RES and HPP – 8.7 % of the total output of the company’s group;

- unit emission of СО2 in comparison with 2019 is owing to the reduction of unit consumption of fuel equivalent (UCFE);

- unit emission of pollutants into air has reduced by 3.5 % in comparison with 2019 indicator owing to an increase in share of generation using RES and share of production by HPP, gas-fired CHP-1, as well as GRES-1, environmental performance of which is better than of other coal-fired power plants of “Samruk-Energy” JSC group of companies;

- reduction of unit emission of SO2 across the group of companies (g / kW * h) by 6%, unit emission of NO by 3% compared to with similar indicators of 2019.

Direct greenhouse gas emissions

|

|

Measurement unit |

volume |

||

|---|---|---|---|---|

|

2018 г. |

2019 г. |

2020 г. |

||

|

Carbon dioxide |

thous. tons |

33 744 |

31 593 |

33 413,98 |

|

Methane |

|

351,98 |

353,850 |

341,6 |

|

Nitrogen oxide |

|

0,293 |

0,275 |

0,296 |

Methodologies: Guidelines for National Greenhouse Gas Inventories, IPCC, 2006; Guidelines for evaluation of greenhouse gas emissions from thermal power plants and boiler houses, Astana, 2010, Appendix 9 to Order No. 280-p of the RK MEPWR dated 05.11.2010. The Republic of Kazakhstan law does not require a mandatory assessment of indirect greenhouse gas emissions, however, we suppose that the indicated volumes of greenhouse gas emissions contain 95 % of total greenhouse gas emissions, including indirect (Scope 1 and 2) of “Samruk-Energy” JSC group of companies, since when calculating direct emissions, SA auxiliary power is taken into account.

Emissions of ozone depleting substances (ODS) and other emissions

|

|

Measurement unit |

volume |

||

|---|---|---|---|---|

|

2018 |

2019 |

2020 |

||

|

Production volume of ODS |

– |

– |

– |

– |

|

Import volume of ODS |

|

– |

– |

– |

|

Export volume of ODS |

|

– |

– |

– |

|

СPersistent Organic Pollutants |

|

– |

– |

– |

|

Volatile organic compounds |

tons |

297,2 |

261,6 |

261,4 |

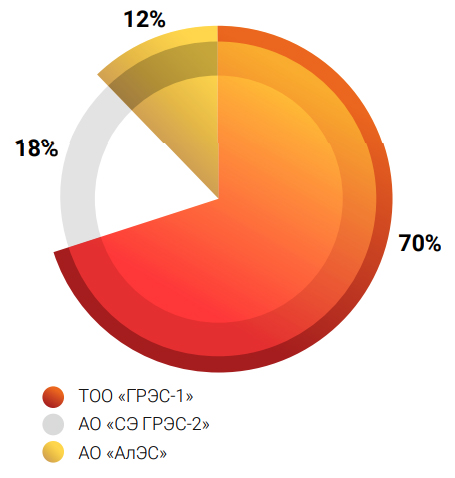

SA input into aggregate emissions of the Company “Generation” sector 2020

Pollutant emissions, thous. tons

Volume of gross emissions across “SamrukEnergy” JSC group fo companies

NOx

SO2

Зола

ASPECT “WASTE”

Explanation of the essential topic and its boundaries

The production process is bound to waste generation, and when managing those wastes “Samruk-Energy” JSC group of companies strive to comply with environmental, sanitary and epidemiological requirements and standards in the field of treatment of certain types of waste.

Taking into account the specifics of operations of “SamrukEnergy” JSC large enterprises, production wastes are classified as large-tonnage – ash and slag waste at TPP and overburden at “Bogatyr Komir” LLP coal mine. These types of waste are non-hazardous and make up most of the total waste. Other types of waste are classified as consumption waste.

Measures regarding them involve separate collection and further transfer of these wastes for recycling or disposal.

Management approach

As required by Kazakhstan environmental legislation, the volumes of waste disposal are controlled. As regards the consumer waste, there are requirements for separate collection and temporary storage in specially equipped places, as well as types of waste that are not acceptable for burial at landfills are determined.

Thus, the types of waste, which are suitable for reuse and classifying as secondary raw materials followed by transfer to corporate entities and individuals, are determined. At “Samruk-Energy” JSC group of companies such wastes include waste paper, cardboard and paper waste, plastic and plastic waste, mercury-containing lamps, scrap of non-ferrous and ferrous metals, electronic and electrical equipment, batteries, tires and their fragments and other hazardous waste.

The total mass of waste by type and method of treatment

|

|

Measurement unit |

Mass |

|||

|---|---|---|---|---|---|

|

2018 |

2019 |

2020 |

|||

|

1 |

Total waste produced, incl |

thous. tons |

79 435,9 |

75 476 |

97 513,5 |

|

2 |

Hazardous |

|

18,8 |

20 |

21,3 |

|

3 |

Non-hazardous |

|

79 417,13 |

75 456 |

97 492,2 |

Evaluation of management approach

Production waste across “Samruk-Energy” JSC group is disposed in the most secure way.

To mitigate the negative impact of “Bogatyr Komir” LLP on adjacent territories, the works on reducing the volume of overburden disposal at external dumps, for this purpose, the projects on using the internal mined-out space of “Severny” and “Bogatyr” open-pit mines as internal. For preventing oxidative processes and prevent spontaneous combustion of coal-bearing rock stored in dumps, measures on isolating dumps with inert rocks and compacting the roof of dumps are taken.

Ash and slag waste of TPP are buried in ash dumps, dust suppression works are carried out as well, at SDPP – under the edge of the water, and at Almaty stations – using a unique combined technology with topping a layer of soil and planting of perennial and shrubs. Reclamation of depleted parts of ash dumps is carried out annually. Overall, the development of hydropower plants and renewable energy facilities also contributes to the reduction of ash and slag waste per unit of production.

At the same time, ash and slag disposal also belongs to production waste management activities – they are used in construction of roads in Pavlodar region. About 10 thous. tons of dry ash were disposed in 2020. However, the demand for ash and slag as a raw material is low

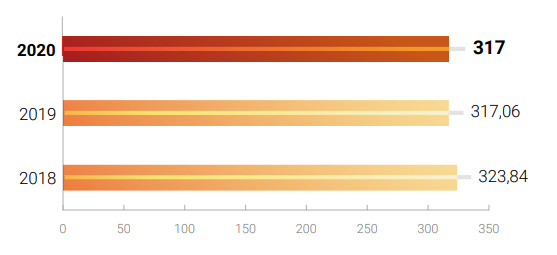

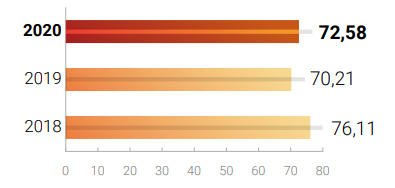

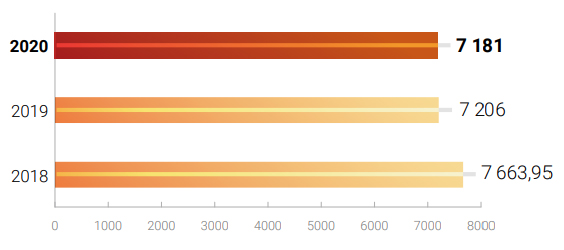

Ash and slag waste, thous. tons

Per unit indicator of ash and slag generation by sector Fuel generation, kg of ASW/kWh